From the production environment to the production equipment and production staff, we strive to meet high standards, with the aim of providing high-quality silicone products.

140+

Production Staff25,000㎡

Production Space2000tons

Annual Production120sets

of Production EquipmentWe have established a systematic production system to work with the QA and R&D departments with the purpose of ensuring the cost-effectiveness of our products.

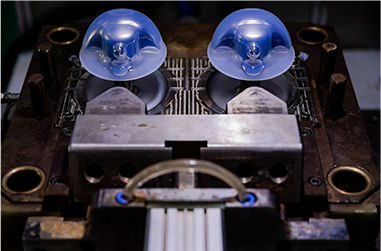

Our own molding department designs and makes the mold that ensures good productivity for each silicone product.

Mix the raw materials with colorant and vulcanizing agents and avoid premature curing. Then cut into strips and roll with plast films to avoid contamination.

The strip materials will be put into the molds, and then into the machine to be heated, pressurized, and finally formed up.

All products will undergo the burring process in the delashing workshop, and workers will ensure that the product surface is smooth.

The products will enter the oven workshop and will stay inside for 4 hours under 200℃. Our ovens are designed for recording the temperature.

We provide post-processing for the product surface and functions including printing, sliting, talc powder spraying, and more.

DX is an experienced manufacturer of silicone products with professional spirit. We have multiple factory certifications such as ISO 9001, ISO 14001, ISO 13485, INTERTEK WCA, and QS.

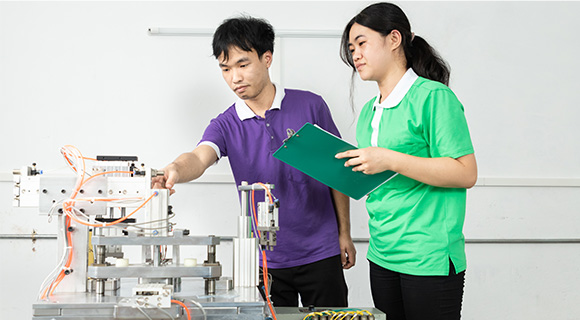

We not only do production but also have a complete system to ensure production efficiency and product quality.

Our capabilities of quality control, R&D, and process improvement are integrated with production. That's why we have a stable and virtuous manufacturing circle.

Comprehensive quality management system and statistical tools help us control product quality.

Learn More

DX‘s own R&D departments and teams provide high-quality technical services to meet customers' various requirements.

Learn MoreDX provides you with all-around silicone product customization services for valued customers like you.