Did you know that silicone tubing is used in the food, medical, and biotech industries? If you are an industrial manufacturing expert, this shouldn’t be surprising. But for someone who’s hearing the name for the first time, you will be amazed at the countless roles silicone tubing plays in many industries. It is flexible but strong. Affordable yet fire resistant. But the biggest question is probably going to be, “what exactly is silicone tubing?” Or rather, where can I use it? And what’s the manufacturing process?

In this guide, we explore the complex world of the manufacturing industry, with specific attention to silicone tubing. We define silicone tubing, its advantages in different settings, the manufacturing process, and some of its best applications throughout different industries.

So, let’s dive right in.

Silicone tubing is a useful elastomer that finds its role in the modern industrial sector. The material’s toughness, heat resistance properties, and durability make it an excellent option in the aerospace, healthcare, food, and marine industries. But it doesn’t stop there.

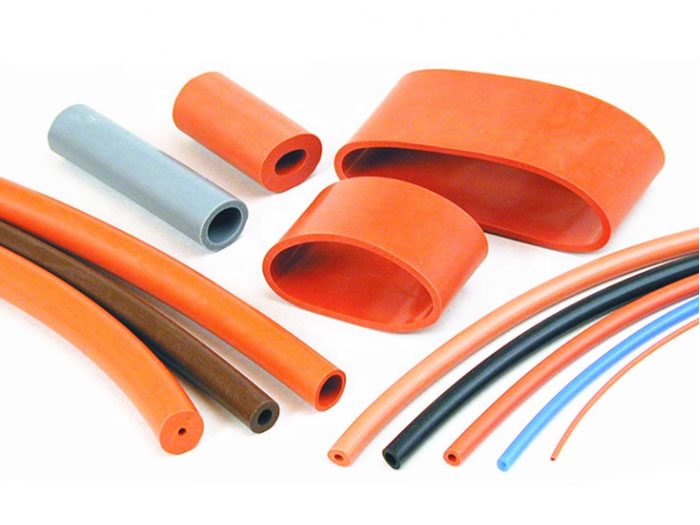

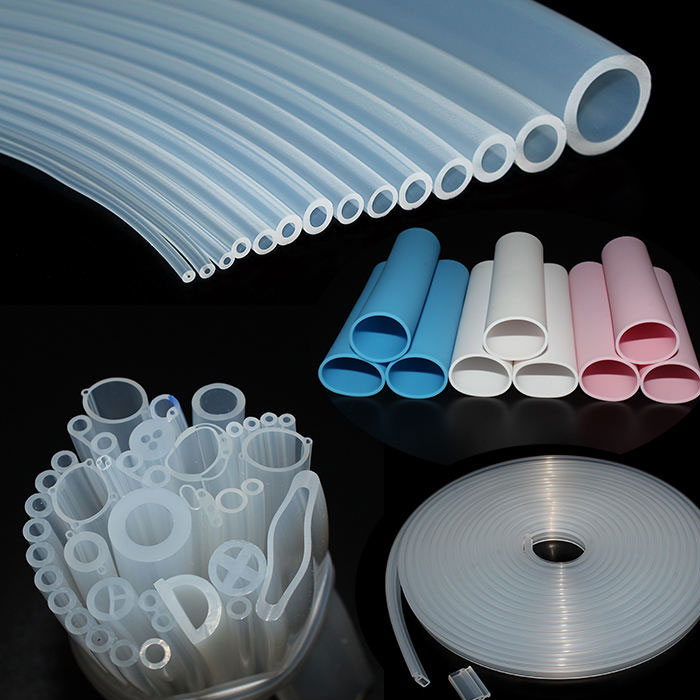

Silicone tubing also has excellent properties that enable it to feature in the electrical industry as well as the dairy processing and automotive sectors. It’s worth reminding that silicone tubing comes in different sizes, from the standard small tubing varieties for liquid and powder transportation to the medium-sized options used in the food and pharmaceutical sectors.

The platinum silicone rubber tubing is sometimes described as an all-rounder, finding its role in the dairy, vending, and medical industries because of its non-toxicity and ability to preserve the desired taste.

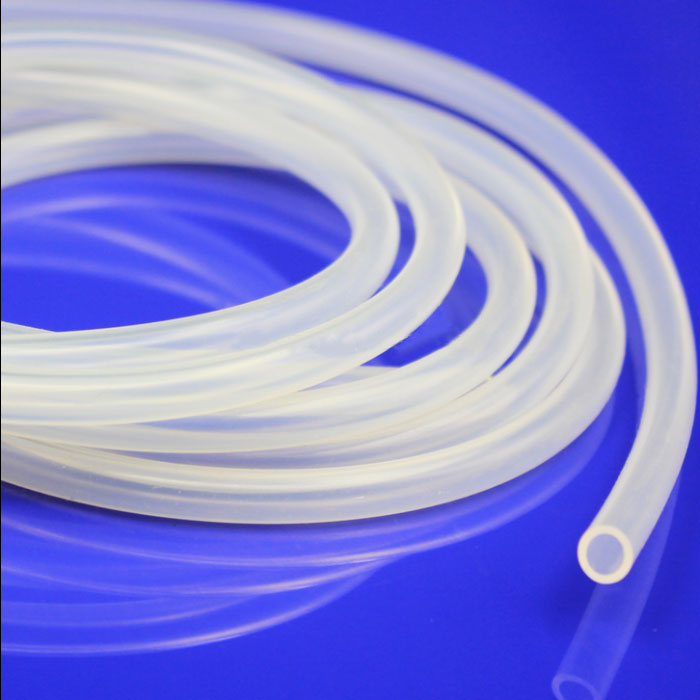

When it comes to classifying silicone tubing by shape, you still get several options, from the transparent dairy tubing to cater to the dairy processing needs to the radiator hosing used in coolers and radiators and the field tubing available in radio controllers.

As expected, silicone tubing is constantly compared to rubber tubing, with many wondering which option makes absolute sense when it comes to everyday use.

While there’s no clear winner between the two options, it’s worth reminding that silicone is a durable product made from conventional rubber but with flexibility, durability, and versatility in mind.

Its excellent ability to tolerate UV rays makes it the perfect option for outdoor, electrical, and sterilized applications.

Below are the top 6 advantages of silicone tubing you may want to know before making your investment.

One of the biggest advantages of using silicone is durability. Unlike other elastomers, silicone is flexible and easily retains its shape under different conditions. Accordingly, it is an excellent choice for critical healthcare, automotive, and aerospace applications.

Silicone is the elastomer of choice where average users crave material toughness, flexibility, and steam resistance.

Shall we talk about its thermal stability? Again, silicone thrives where other elastomers have failed, easily retaining its shape in extreme conditions. Silicone’s guaranteed thermal resistance means it can maintain its structural properties and shape over a varying temperature range.

Research shows that silicone tubing can tolerate extreme temperatures from as low as -130°F to as high as 600°F. If that’s not the true definition of reliability, what is?

The only reason silicone finds its applications across multiple industries is its versatility. No matter your design idea or manufacturing needs, you can count on silicone to give you the perfect shape, even when working on more complex projects.

Whether you want the medical-grade option for use in pharmaceutical settings, FDA-grade silicone tubing for use in the food and beverage sector, or the high-temperature variety for aerospace applications, silicone tubing seems to tickle all the right boxes.

If color matters to you, you will be delighted with the many variations that come with silicone tubing. Such an underrated advantage enables you to choose the most suitable material for specific applications.

Silicone tubing is one of the easiest elastomers to color just before the curing process, giving it a beautiful, resilient shade depending on the client’s specifications. Depending on the desired application, you can choose translucent, red, black, white, or other colors in different sizes.

Is there a more fulfilling experience than working with a durable elastomer that’s also UV resistant? Silicone tubing tolerates UV radiation, toxicity, ozone, and pathogen growth, making it a safer option in food processing and medical industries. That also alleviates any worries of potential degradation in UV light exposure.

Combining this property with its kink resistance, durability, and tear resistance abilities, you will discover why silicone is the material of choice for many outdoor applications.

Of course, we can’t fail to mention the most underrated advantage. Silicone tubing is easy to manufacture. That implies manufacturers can easily twist its shape and size to suit any design idea and specifications.

When you contact the right manufacturer, you get high-quality standard and custom silicone tubing made with precision.

Silicone tubing is also widely accepted in many industries because of the following reasons;

As you may already know, silicone tubing is a product of silicone rubber manufactured through extrusion. Generally, the process involves rubber treatment to accommodate a range of properties that make silicone the material of choice in many industrial settings.

Here’s a summary of the extrusion process to give you an idea of what goes on behind the scenes.

When everything begins, the manufacturing experts must feed the desired rubber compound into the extruder. This simple procedure heats the material to create the desired shape.

Then, the experts pass the rubber compound to the screw before transferring it to the die in the next step.

While inside the die, the manufacturing experts fit the rubber compound according to the desired measurements (thickness and diameter). The resulting pressure and temperature rise give the material its new shape, which should match the cross-sectional design of the die.

Simply put, vulcanization is the process of heating rubber using sulfur, an activator, and an accelerator at a temperature range of 140°C–160°C.

It’s a vital step in achieving the desired resilience, elasticity, weather resistance, viscosity, and hardiness. The exact procedure will vary from company to company, even though sulfur treatment has been the conventional way of completing the vulcanization process.

With better technologies, the industrial manufacturing sector has seen an upsurge of new options such as microwaves, extreme heating, and applying salt baths to complete the vulcanization process.

Silicone tubing is the epitome of resilience, durability, and versatility. And it’s little surprise that it’s well-suited for use in many industries, including aerospace, medical, food, automotive, and marine.

In the next section, we describe the role of the silicone tubing in each of these sectors;

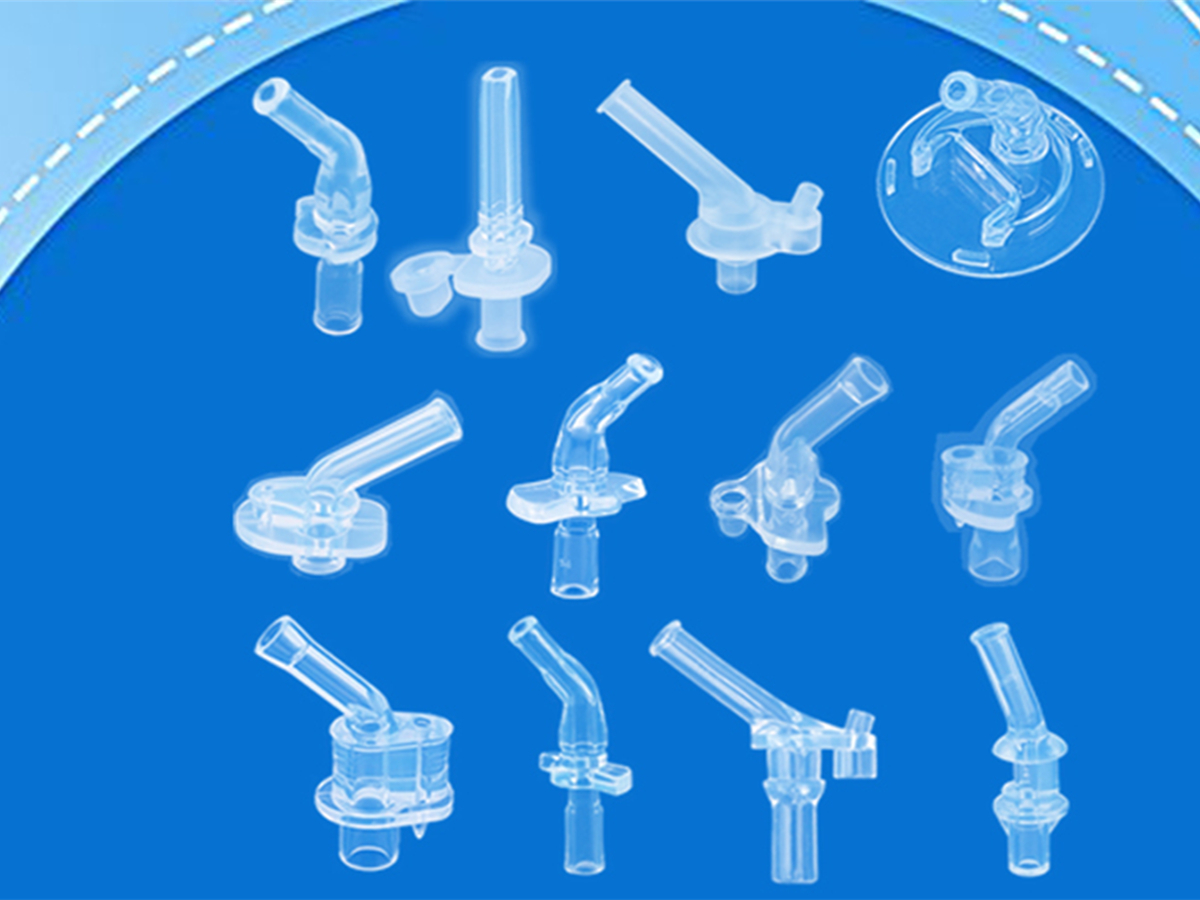

You may already know that silicone tubing is durable and easy to sterilize. But one of the key features making it a desirable material in the medical industry is that it is neither harmful nor poisonous to living tissues. That alleviates potential worries of unexpected allergic reactions or chemical toxicity.

In the healthcare industry, medical-grade silicone rubber is used to design respirators, medical implants, feeding tubes, peristaltic pumps, surgical drains, and tubing. Platinum silicone tubing, in particular, is widely accepted in this field because it maintains taste without tainting its content.

Whether knowingly or unknowingly, we bet you’ve spotted a silicone component in the automotive industry. Here, the silicone hose is commonly used for transporting fluids throughout the vehicle.

Its excellent heat and moisture resistance properties make it the material of choice for insulating the electrical parts of automobiles. What’s more, silicone tubing holds up well against corrosion, and you are likely to spot it in many components of modern SUVs, cars, and trucks.

We mentioned that silicone tubing is highly tolerant to extreme weather conditions. No matter how you look at it, that’s a valuable property in the aerospace industry. Its flexibility also makes it popular in this sector and incredibly useful in making fluid conveyance and climate control systems. Because of its strength, silicone tubing is also useful in creating vacuum seals for large and small airplanes.

Silicone tubing also plays a vital role in the aquatic world, serving as drainage hoses for showers, cockpits, and sinks. Moreover, silicone hoses are a vital part of the ship and boat engines with an even bigger role in transferring fluids in on-ship components.

Of course, we can’t fail to mention the role of strong silicone hoses in offshore environments where they are commonly used to deliver oil to the standby vessels.

An ideal food-grade tubing is not only flexible and lightweight but also reliable. Above all, it should be sterile and resistant to acids, chemicals, and alcohol. That’s a rare combination you will only find in silicone tubing.

In the food, beverage, and dairy processing industries, silicone tubing helps in yeast harvesting in breweries, dispensing ingredients and flavorings, metering liquids, and dispensing finished products like juices.

DX is a trusted manufacturer of silicone products boasting 31 years of experience in the manufacturing industry. It is committed to providing silicone and silicone products that give real business value while working with you through every step, from product design to the actual silicone product manufacturing.

The DX team is respected for converting every client’s dreams into reality, delivering silicone parts with cutting-edge technology, unmatched precision, and unbeatable quality. We supply silicone products for use in all sectors, including health and medical, automotive, food and dairy processing, sports, and outdoor, among the rest.

Silicone tubing is a durable, versatile, and reliable elastomer widely appreciated for its thermal tolerance abilities. With plenty to offer yet quite affordable, silicone tubing finds its role in several industries, including medical, food and beverage, marine, automotive, and aerospace, as we’ve mentioned above.

Silicone tubing is your best bet if you need an easily customizable material that offers value for money. Get in touch with the experts at DX today to learn more about our silicone tubing products and how we can turn every design idea into reality without straining your budget. It’s all in minor detail, and that’s precisely why we are here!

DX provides you with all-around silicone product customization services for valued customers like you.