Silicone’s versatility and unique properties make it a popular choice for prototyping across various industries. From medical devices to consumer electronics, silicone prototypes offer a realistic feel, exceptional functionality, and the ability to iterate quickly. But with numerous silicone prototype manufacturers available, selecting the right partner can be a challenge. This blog post will equip you with the knowledge to make an informed decision.

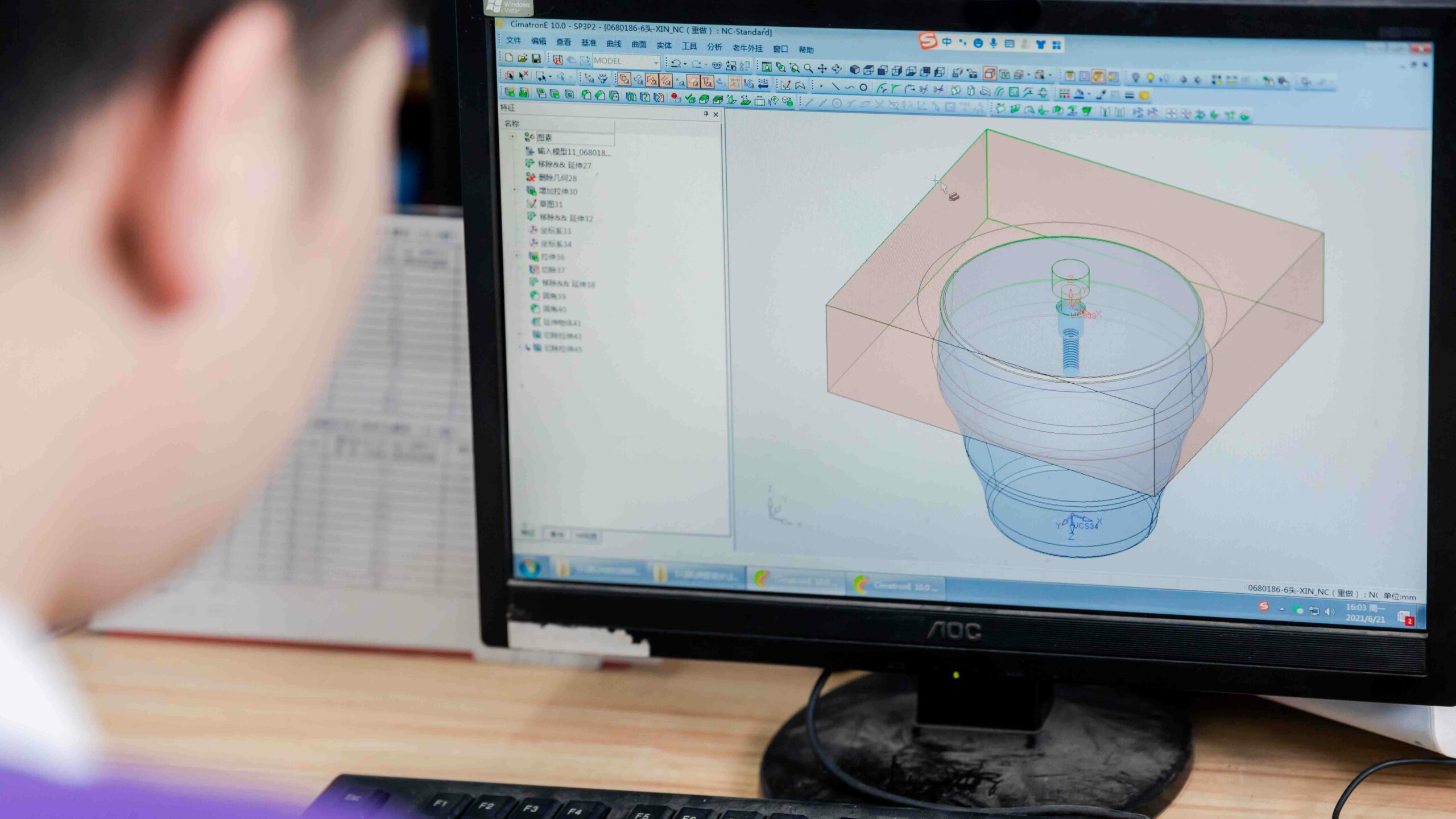

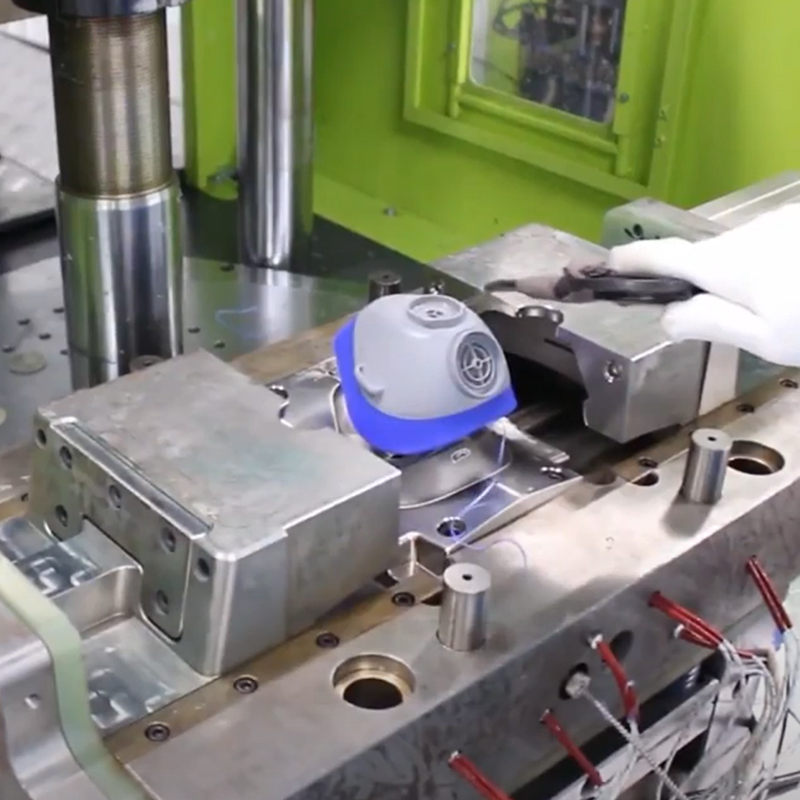

At DX, we understand the significance of high-quality silicone prototypes in product development. Our team of experts possesses extensive experience in crafting functional and visually striking silicone prototypes across diverse industries, including home appliances, maternal and infant products, medical devices, and the automotive sector. We leverage cutting-edge technologies and maintain stringent quality control measures to deliver exceptional results. Additionally, we offer a comprehensive range of silicone rubber product manufacturing processes to bring your vision to life, including:

Ready to Discuss Your Silicone Prototype Needs?

Contact DX today! We’ll guide you through the prototyping process and help you bring your innovative ideas to life.

DX provides you with all-around silicone product customization services for valued customers like you.